In this article, we will give you a complete guide on how Embroidered Patches are made, what type of equipment is needed for Embroidery and which types of materials work best for Embroidery Projects.

What is an Embroidery Patch?

Cloth patches or Badges are pieces of embroidered fabric in different sizes(1"-30" width), which can be iron-on or sewed on, or sticker on the fabric or cloth, hat, bag, shoe, and so on.

According to Wikipedia, “an embroidered patch, also known as a cloth badge, is a piece of embroidery which is created by using a fabric backing and thread. The art of making embroidered patches is an old tradition and was originally done by hand. High-speed, computerized machines have led to mass production.”

As you can imagine, producing patches needs a lot of processes. from designing patch and thread options to embroidery and adhesive and heat cut to quality check and packing.

As a professional manufacturer of embroidered patches - Miakapatches introduce ----How is the embroidered patch made?

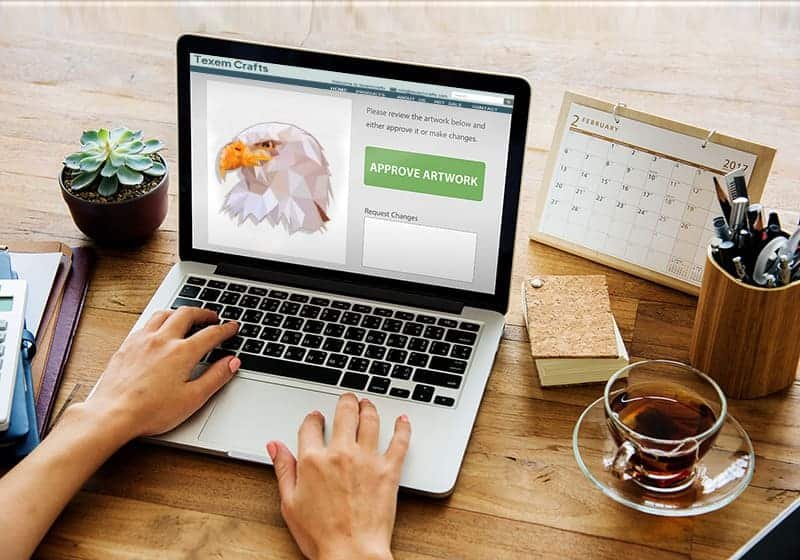

Step 1: Design the patch

Step one is to design the Embroidered Patch. Embroidery Patches can be made up of several different components, including a fabric backing (the part that will be stitched onto an item), embroidery thread (what creates the image), and heat-pressed adhesive (to keep it attached). Designs for Embroidered Patch can be searched through the internet, a desire of the customers, drawings, or company logo symbol. Upon receipt of your artwork, even if it is an idea, our professional designers will provide you with a viable embroidery marker draft for your reference and selection.

Step 2: Select the fabric and thread color

The next step in Embroidery Patch production is to pick out the fabric and embroidery thread. Embroidered Patches are made of a variety of fabrics, such as cotton or polyester. Embroidery Thread comes in many different colors and designs that range from solid (one color) threads to multi. To be proud, all material that Miakapatches used is passed OEKO and Reach certification.

Step 3: Embroider the Patch

Having an ideal pattern and finalized material, we can press the button of the embroidery machine to create nice patches! Embroidery Patches can be made up of several different components, including a fabric backing (the part that will be stitched onto an item), embroidery thread (what creates the image), and heat-pressed adhesive (to keep it attached). Almost all of Miakapatches's patches are produced using Tajima and Barudan Japan embroidery machines, 6 laser cutting machines and 10 auto cutting machines, and a heat press machine. Embroidery machines are connected through the Embroidery Machine Connection, which provides automation to multiple machines.

Miakapatches will not stop at this point until you get satisfied with your order! We have a quality control team for each step of production mentioned above, plus our QC department is responsible for all final inspections before shipment.

Step 4: The Backing

After finishing the embroidery process, the uncut material is passed through a heat press machine, which uses pressure and heat to bond the hot melt backing to the fabric used.

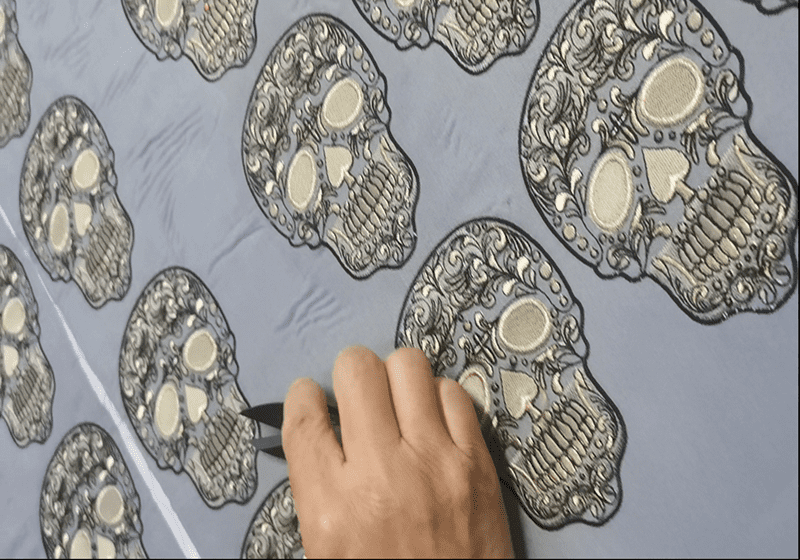

Step 5: Quality Checking

All embroidered patches are checked once more before being cut and packed. Workers will remove excess or loose threads as well as pick out inferior pieces.

This step looks simple, but it is very time-consuming. Many factories often omit this crucial step to save costs. For better quality, Miakapatch has strict quality control to ensure that all embroidery patches received by the customer are perfect.

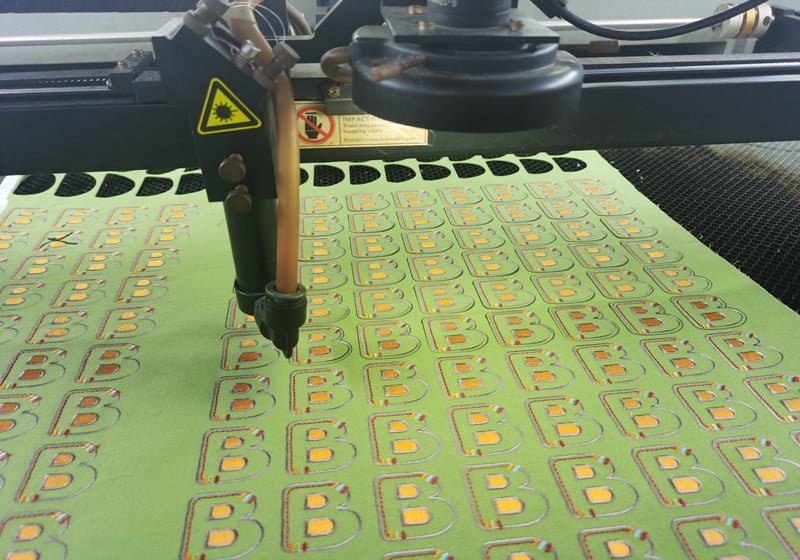

Step 6: Cut and Pack Patches

The final step in unfinished Embroidered Patch production is to cut the embroidery patch into individual pieces. Laser and heat cutting are the two most common ways of cutting embroidery patches.

A laser cutting machine is generally used for simple shape patches, such as circles, squares, or regular graphics. It is efficient and fast and once the cutting layout is confirmed, all products are more uniform. However, laser cutting is limited by the material of the fabric, so thicker fabrics or those with self-adhesive paper are not suitable.

Heat cutting is generally done manually with electric stamping rods and with automated heat-cutting machines. Manual heat cutting can meet complex shapes and ensure that the embroidery label is no extra border, but is slow and costly and is often used for high-end quality. Again manual heat cutting can meet complex shapes and ensure that the embroidery label is a perfect border, but it is slow and costly. Mostly, high-quality items will use heat cutting way.

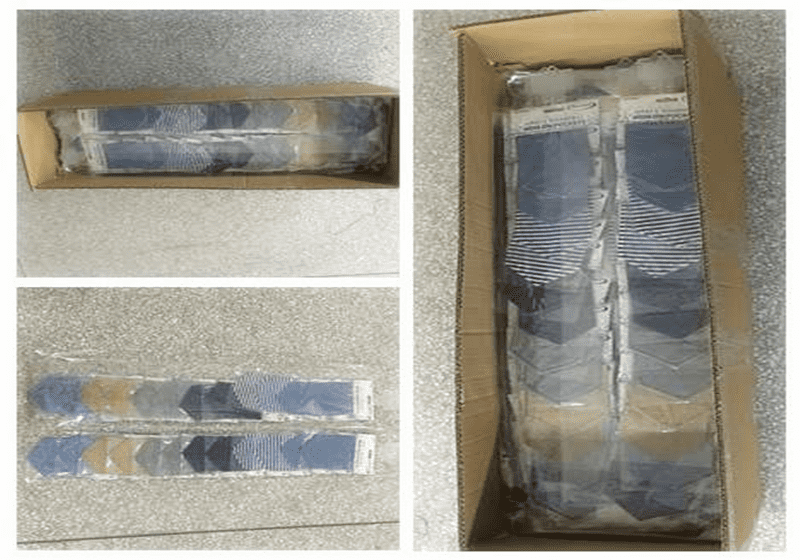

Step 7 Packing and Shipping Embroidered Patch

Miakapatches will make the package for each customer's order, from labels to packaging materials. Then it is time to pack up your patches! Miakapatches can provide the package as any customer requires. In general, there are four regular Packaging solutions, bulk pack, patch with barcode, single patch card、hang tag. Of course, if you have any ideas about the package, just tell us and we will finish it as per your instruction.

The final step of Embroidered Patch production is boxing them up and sending them to the customers~

Package 1: Patch in bulk

This type of packaging is mostly used when the buyer is a garment manufactory and the importer or wholesaler needs to label the packaging again.

Package 2: Patch in OPP bag with label

This is the most popular packaging way on Amazon. Low packaging costs and high efficiency make it perfectly suited to fast orders. The absence of over-packaging has become a trend. What's more, simple and safe packaging will save a lot of freight costs when shipping costs are constantly rising. At the same time, there is no need to worry about breakage.

Package 3: Patch with a single card & barcode label

Buyers are usually shopping malls, retail shops, or supermarkets. as well as some high-end online shops. Printing paper cards and barcodes can be customized according to customer requirements. Prices can vary considerably depending on the quantity.

Our factory has worked with Walmart, Lidl, Hobby Lobby, and many branded retail shops for many years, No matter how complex your packaging is, just leave it to us with confidence.

Package 4: Patch with hangtag

This is one of the most common promotional packaging in supermarkets. It doesn't take up much space and can be hung on the back or side of any shelf, making it easy to restock and convenient for consumers to buy.

With an eye-catching advertising sign, it can often become a pop-up product.

Conclusion

Miakapatches deliver Embroidered patches worldwide by air, sea, or express! After your order is completed, our sales team will send you an email and you can track the shipment status of the order in time.

These 7 steps are all processes of producing embroidered patches, many Embroidered Patch manufacturers will try to skip some of the steps to reduce costs. However, Miakapatches takes great pride in ensuring that all our embroidered patches are made with high quality and care throughout every step of production!

Contact us to grow your embroidery patches business!