Custom patches are more than just decorative items; they serve as a powerful form of self-expression, branding, and personalization. Whether it's for fashion, teams, or companies, the right patch can speak volumes about style and individuality.

patches

patches

Custom patches are widely used for branding purposes, fashion trends, and team identification. However, they also serve as a tool for artistic expression, making them a versatile accessory for people of all walks of life.

Types of Custom Patches?

Custom patches come in various types, each offering different materials, designs, and application methods. Some patches are more suitable for certain tasks or industries than others, depending on the needs and preferences of the client.

There are four primary types of custom patches: embroidered, woven, PVC, and leather. Each has its own set of characteristics that make it ideal for particular applications, so understanding these differences is crucial when choosing a patch for your project.

Embroidered Patches

These are made using thread to stitch the design onto a fabric backing. Embroidered patches offer a classic, high-quality look, with intricate details that give them a textured appearance. They are often used for logos, branding, or team insignia. Embroidery provides durability and can withstand washing and heavy wear.

Woven Patches

Woven patches are made with threads woven together to create a smooth, flat finish. Unlike embroidered patches, woven patches can capture fine details with greater precision. They are perfect for designs that require more intricate patterns or logos with small text or fine lines.

PVC Patches

PVC patches are made from soft rubber-like materials, which make them flexible and durable. These patches are often used for tactical gear, military uniforms, or sports teams. PVC patches can withstand extreme weather conditions and can be molded into various shapes, giving them a three-dimensional effect.

Leather Patches

Leather patches are a more premium choice, offering a sophisticated, timeless look. They can be embossed or debossed to create texture and are often used for upscale fashion items or rustic-themed apparel. Leather patches have a rugged aesthetic and are often used on items such as jackets, bags, and hats.

Each type of patch serves a unique purpose, so it is essential to choose the right one for your needs. Whether you're aiming for durability, aesthetic appeal, or intricate design details, understanding the materials and application methods will help you make the right choice.

design the patches

design the patches

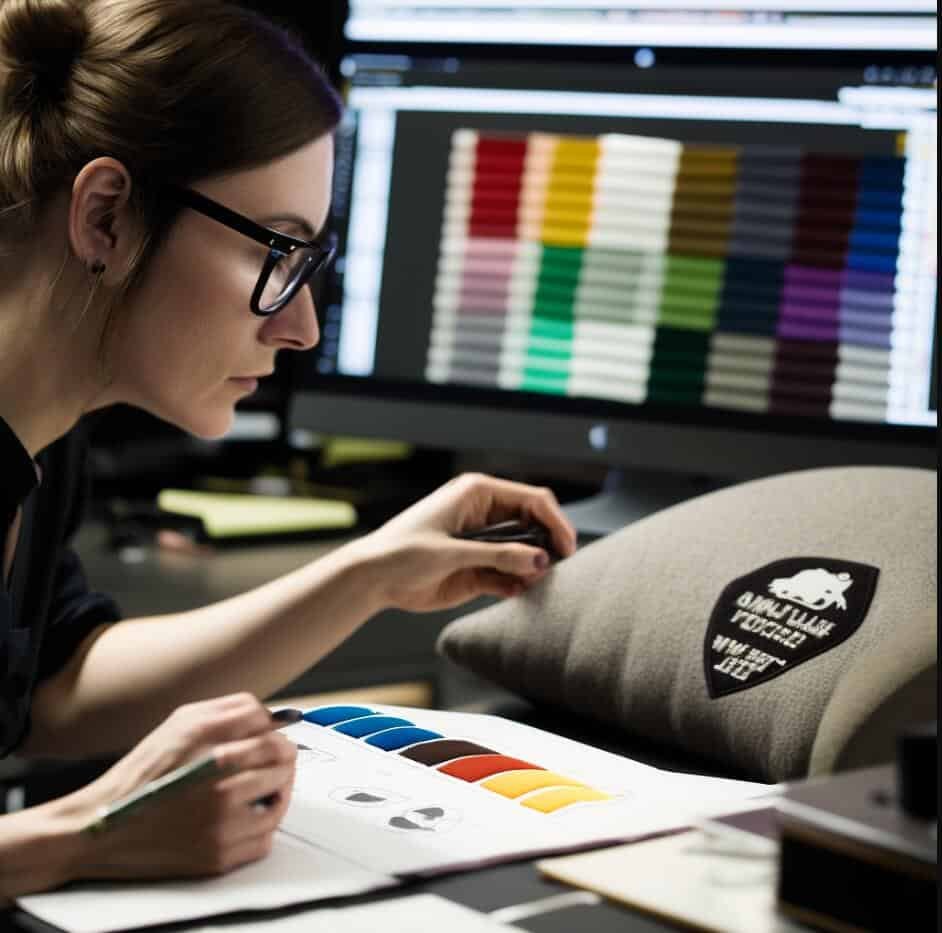

How to Design Your Custom Patch?

Designing your custom patch might seem like a daunting task, but it's actually a creative and straightforward process when you follow a few basic steps. The design of your patch can influence its overall effectiveness and appeal.

To design a custom patch, you need to start with an idea and focus on translating it into a design that will look good on fabric. It's important to consider the size, colors, and details of the patch as these elements will directly impact how it appears when applied to a garment or accessory.

When designing a custom patch, start with a clear vision. What message or theme do you want to convey? Do you want the patch to reflect your company’s branding, a specific team, or just a personal design? Once you have an idea, the next step is to think about size and color.

Size and Shape

Consider how large or small you want your patch to be. Patches can be any size, but for practical purposes, they are usually designed between 2 to 4 inches in diameter. Keep in mind that the more detailed your design is, the smaller your patch should be to ensure the details are visible. Also, think about the shape—round, square, rectangular, and custom shapes all have different visual effects and can change the overall look of the patch.

Colors and Materials

Next, think about the colors that will best represent your design. Custom patches offer a wide range of colors, but some designs might work better with certain shades. Also, the choice of material will play a role in how your design appears. For instance, embroidered patches offer a slightly different color profile than woven patches. Make sure to work with your manufacturer to match the right materials to your design for the best result.

Simplicity vs. Detail

Simplicity is often key when designing a patch. Intricate designs may look great on paper but can become difficult to reproduce with certain methods, such as embroidery. You should aim to strike a balance between creativity and practicality. Consider whether your design will translate well to fabric and whether it's scalable for different items.

Working closely with an experienced designer can help bring your vision to life. The key is clear communication about the type of patch you want and how it should look when completed.

Are patches better than embroidery?

Custom patches and embroidery are often seen as two different options for customizing clothing, but they aren’t necessarily in competition. The best choice depends on the intended use, look, and durability you're aiming for.

Patches have several advantages over traditional embroidery, especially when it comes to intricate designs or adding a unique touch to your product. They can be used on a wider range of fabrics and materials, and they often offer a more durable finish.

Patches offer several benefits over embroidery, such as faster production time, versatility in application, and less impact on fabric wear. Embroidered designs are often stitched directly onto the fabric, which means they can cause wear and tear on delicate fabrics over time. Patches, on the other hand, are applied to the surface, preserving the integrity of the fabric.

Durability and Versatility

Patches tend to be more durable because they are typically made from more robust materials like polyester, vinyl, or leather. They can also be applied to a wider range of fabrics, including those that may not be suitable for direct embroidery, such as leather, vinyl, or delicate fabrics.

Embroidery, though classic, can be more prone to fading and wear after repeated washing. The stitches may unravel over time, especially with heavy use, while patches remain intact. Additionally, because patches can be easily replaced, they offer more versatility in terms of design changes or updates.

Design Complexity

Patches, particularly woven or PVC patches, can handle intricate designs better than traditional embroidery. Fine details such as text, logos, or patterns are more easily reproduced in patches without losing quality. In contrast, embroidery is better suited for designs that are simpler or larger in scale.

Cost

Although the production cost for patches can vary based on the design and material, they can be more cost-effective than embroidery, especially for larger orders. Embroidered designs may require more time and labor, increasing their overall cost.

When deciding between patches and embroidery, consider factors like material, durability, complexity, and cost. Each has its strengths, but patches offer greater flexibility in many cases.

Conclusion

Choosing the right type of custom patch, designing it well, and understanding how it compares to embroidery can help you create the perfect product. Always communicate your expectations clearly to get the best results.