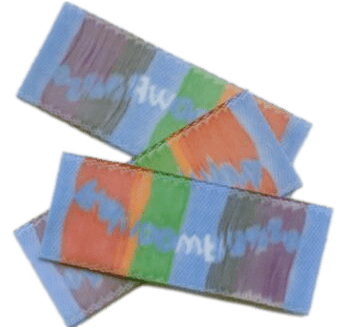

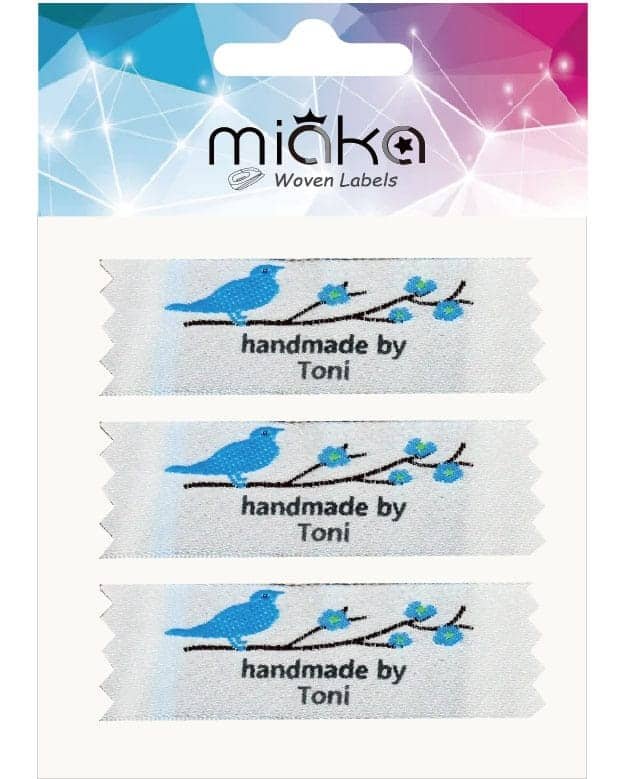

the whole process of making WOVEN LABEL

This is what we do when it comes to making custom patches:

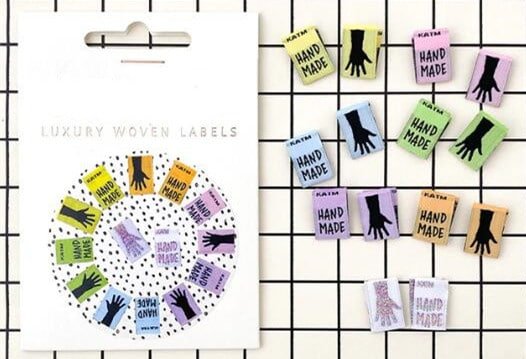

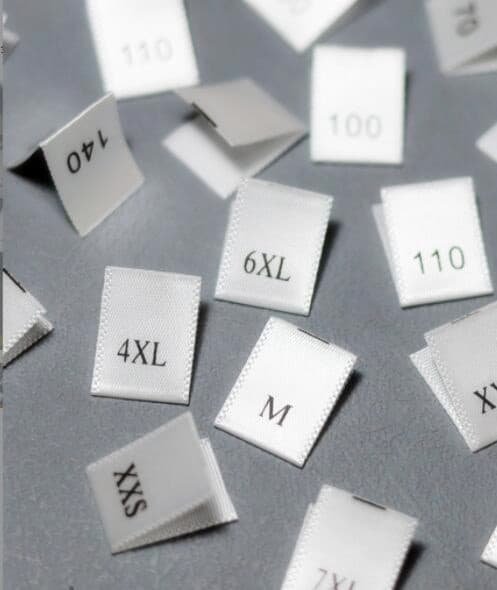

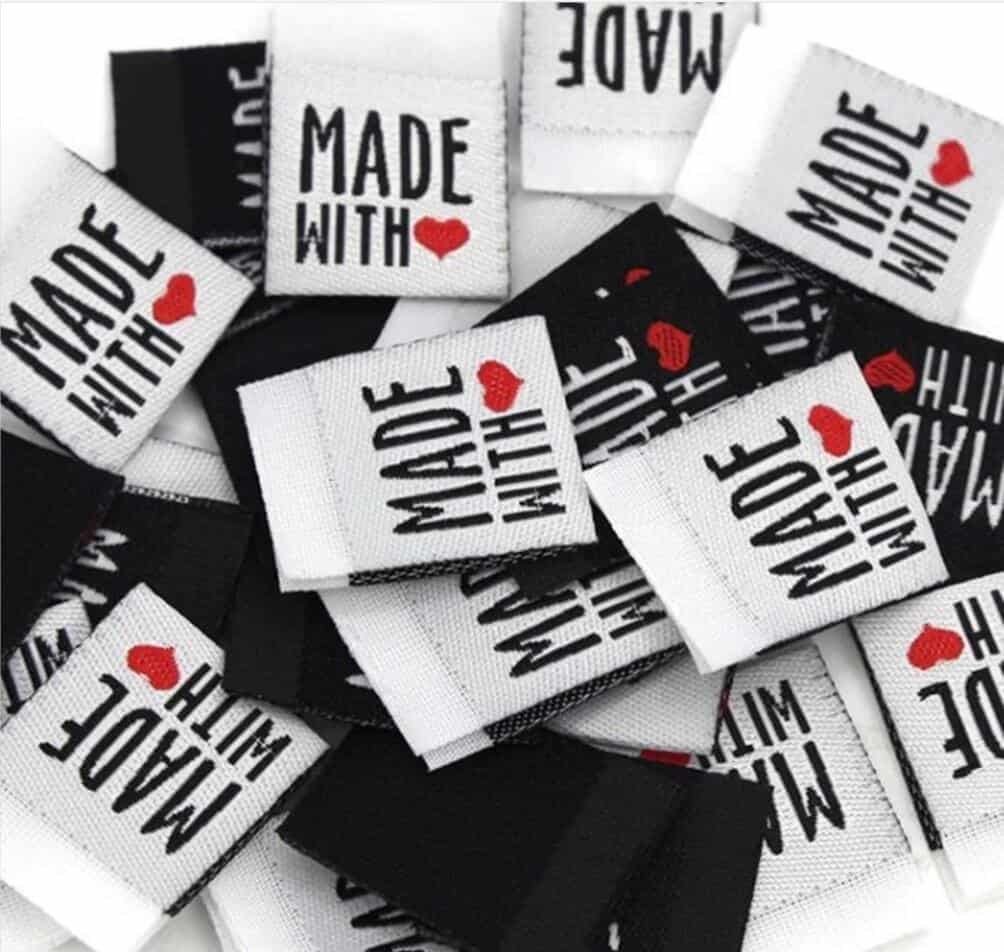

Step 1: Pick your LABEL STYLE

Identify what style and size of label you’d like to make and how many you want. and we will quote an initial price based on your artwork and information(size/qty/pack and so on).

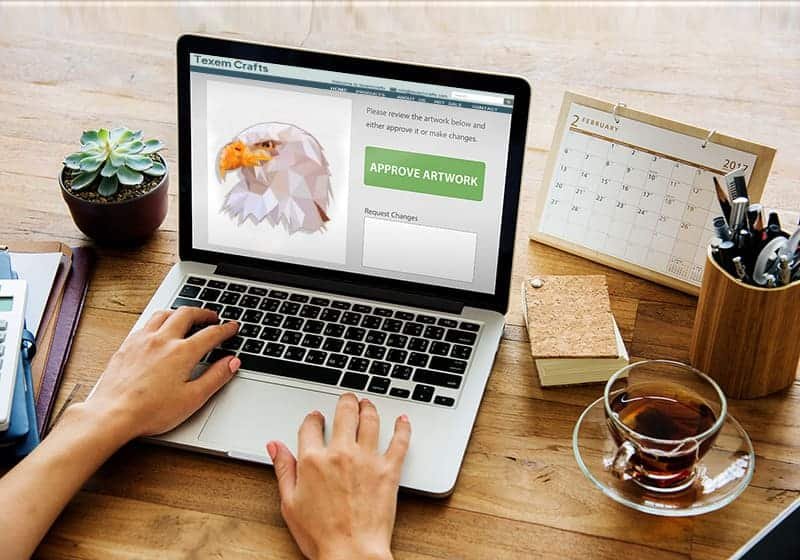

Step 2: APPORVE ARTWORK

Our experienced artists will work with you to create the label possible. Not only full service but also provide professional advice to meet all of your needs.

Step 3: WOVEN

Print out the artwork on a special piece of sublimation paper. and heat press to the back of the patch material. We import the latest sony multi-color printing equipment

Step 4: CUT & FOLD

The type of equipment needed to cut and fold labels varies depending on what the customer needs. You can talk with us directly about what you want.

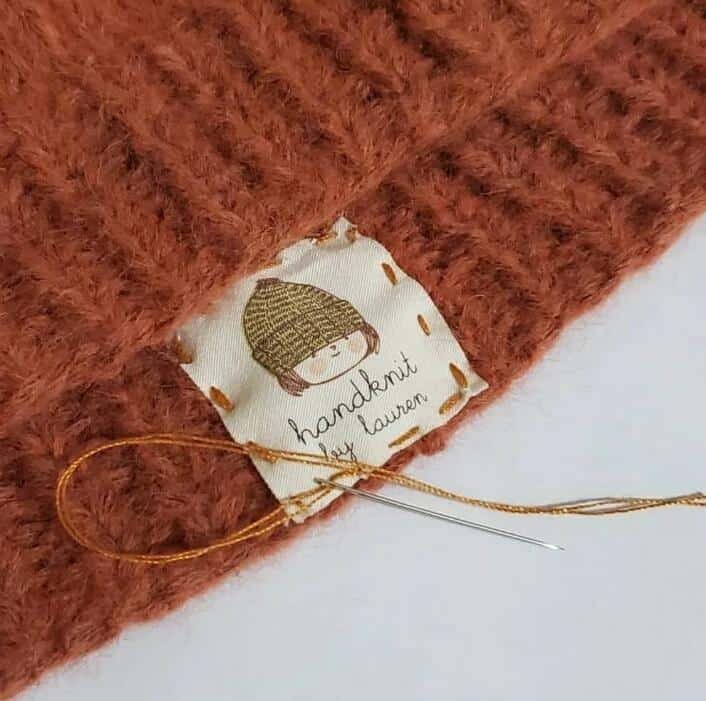

Step 5: Quality Checking

Workers will pick out inferior ones before packing. Miakapatches has strict quality control to ensure that the labels are perfect.

Step 6: Pack & ship

As customer’s different requirements, Miakapatches provides bulk/retail bag packages or different packages for your selection.